How You Can Save Thousands on Dental Supplies

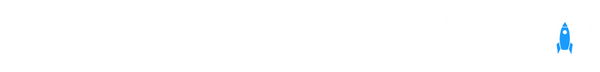

Supplies… Can’t live without them, but it is often the cause of dental team nightmares. At least daily I hear of concerns regarding the time it takes to place orders, running out of bone graft before the 2 o’clock extraction, misplaced and expired products, etc. Over the years I found that a strong inventory management system provides streamlined efficiency and overall cost savings.

Main Storage

The main storage holds most of the inventory. Shipments are unpacked and restocked here. Tip out bins are an efficient way to store, manage, and distribute inventory. Tip-out bin source: https://simplastics.com/bins-containers/dentalWith this system barcodes/item codes can be placed on the front of each bin. The main storage should hold about one month’s worth of product eliminating bulk purchases and overstock. Larger items may be stored in the tip out bins; however, this can be challenging if there is limited space. Weekly, team members should restock individual operatory rooms with the common essentials, such as Caviwipes, chair covers, barriers, etc. From the main storage we also refill the “Tub System.” Team members can easily see when inventory is low eliminating hours of searching through cabinets while placing orders.

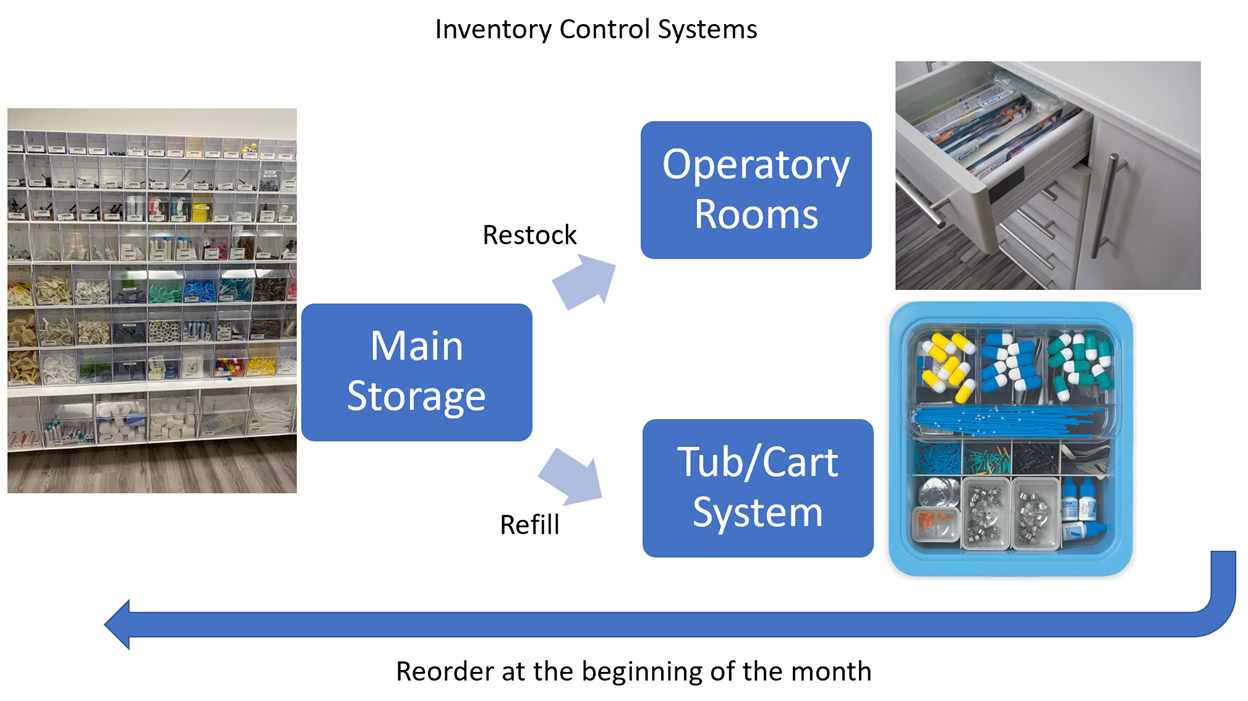

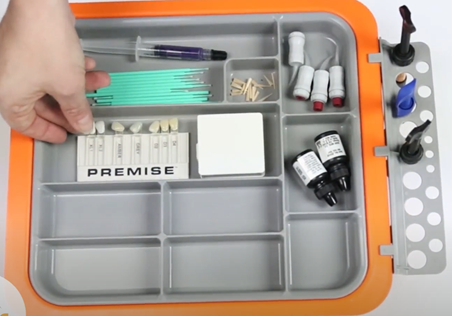

Tub System:

Each day or week team members would refill color coded procedure specific tubs, such as a surgical tub, restorative tub, endodontic tub, orthodontic tub, etc. Fun fact: dental assistants often run back to the storage area 3 – 5 times during a procedure for items that are not readily available. These tubs eliminate that issue because they hold frequently used items and are taken into operatory rooms during each procedure ensuring product availability and increasing chair time efficiency. This reduces waste because they must constantly cycle through the product in the bins before pulling more from the main storage. I have seen thousands of dollars in wasted product after they are placed in drawers/cabinets only to be forgotten about and recovered after their expiration date. Here’s a link for more info on tubs: https://www.zirc.com/products/dental-tubs.

Procedure Trays:

Procedure trays and cassettes can be color coded per doctor/procedure. Cassettes keep instruments together for easy reprocessing, increasing the longevity of instruments, while reducing the chance of injury. As a side note, OSHA requires soiled instruments to be transferred from operatory to sterilization in a locked container and these procedure trays would work. https://www.zirc.com/products/dental-instrument-trays

Ordering:

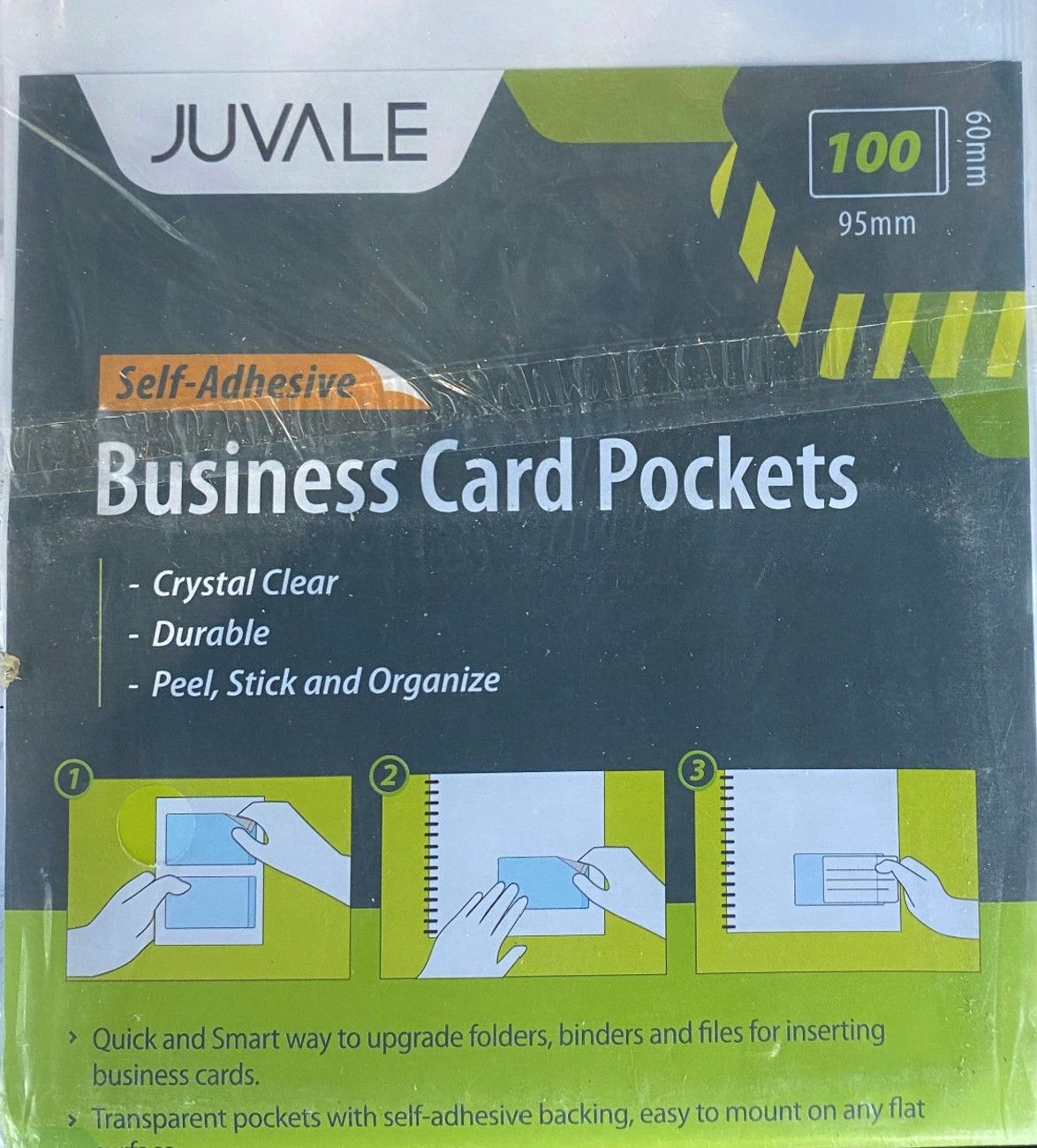

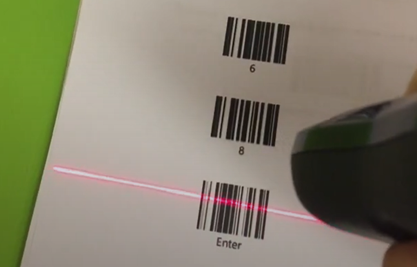

The ordering assistant will restock all rooms and tubs at the end of the month. Barcodes and item codes can be inserted into business card holders and placed on the front of corresponding tip out bins. They can use a barcode scanner to scan barcodes, inputting them into an online ordering platform.

Since there is a clear flow of product from the main storage to individual operatories and tubs it ensures that the product is accounted for, ordering time/process is simplified, and efficiency increases during procedures. Even after employee turnover it will be much easier for team members to adapt to this system.

Tip-Out Bin Logistics

The tip out bin system is broken down into 2-foot width columns (outlined below in red) and the individual rows are stacked on top of each other. I typically recommend 6-8 feet of continuous space to allow sufficient room for the bins. A 6-foot row would be three 2-foot columns of tip out bins. Busier offices could potentially use 8 feet or even 10 feet of tip out bins. In the closed position the larger bins are about 9 inches deep and when opened they extend to about 14 inches deep. These should be installed by a handyman or contractor, but I highly recommend ordering their brackets as it will significantly reduce the number of holes in the drywall and installation time. At the time of writing this article (February 2022) we have completed 6-foot setups under $1800 for the hardware and $200-$400 for the install with a foot-print of 6 feet by 1.5 feet. They can be installed into cabinetry; however, it can be tough to fit, and you will likely have significant dead space with too many holes to count. You will often have dead space between the end of the bins and the interior wall of the cabinet. Partnering with your preferred distributor they can often strategize with you to ensure a successful implementation of a tip out bin system in your office. If you’ve made it to this point in the article, I appreciate you reading. Here is a discount code that does not provide any affiliate commissions to me. I have no affiliation with Simplastics.com but I highly recommend their product. Discount Codes: “PAT11” or “PATT11”

Links to commonly used Simplastics Tip-out Bin packages:

https://simplastics.com/sim66wf

https://simplastics.com/sim64131wf

Thank you for reading! Please consider subscribing to the occasional free email resource.

Contact:

Benjamin (Ben) Holguin

Email: Contact@TheDentalRocket.com

Text/Call: 714-560-3472